Plate Bearing Tests for Wind Farms

Earth Environmental and Geotechnical Ltd Consultants for Renewable Energy Sector

Plate Bearing Tests for Wind Farms & Renewable Energy Sector

Before wind turbines, heavy machinery or temporary structures on a wind farm are installed it is essential to have an understanding of the ground conditions and what equipment and structure the ground can support.

Plate Bearing Tests Are Used for Designing & Safety Testing Wind Farms.

The plate bearing tests are used to confirm that the lift off plans and wind farm design can be safely installed on the planned development site. Plate bearing tests may be required for several locations throughout wind farm including:

-

Wind Farm Access Road

-

Temporary Structures and Working Platforms

-

Piling mats

-

Crane bases

-

Testing of bases & shallow foundations for temporary buildings and structures

-

Site of the Wind Turbines

Plate bearing test (also known as “plate load”) is one of the in situ investigations used during the planning and construction of wind farms. The results of the Plate Bearing Test are used to confirm that roads and hardstand designs meet the minimum requirements for compaction and bearing capacity. The results are also used to confirm that the Wind Turbine installation designs are appropriate for that site.

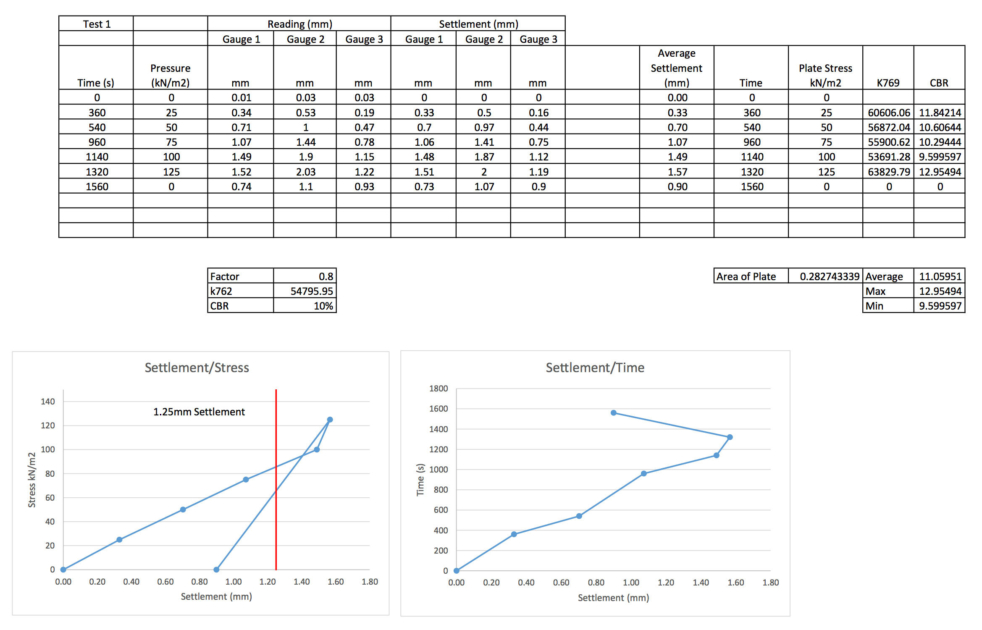

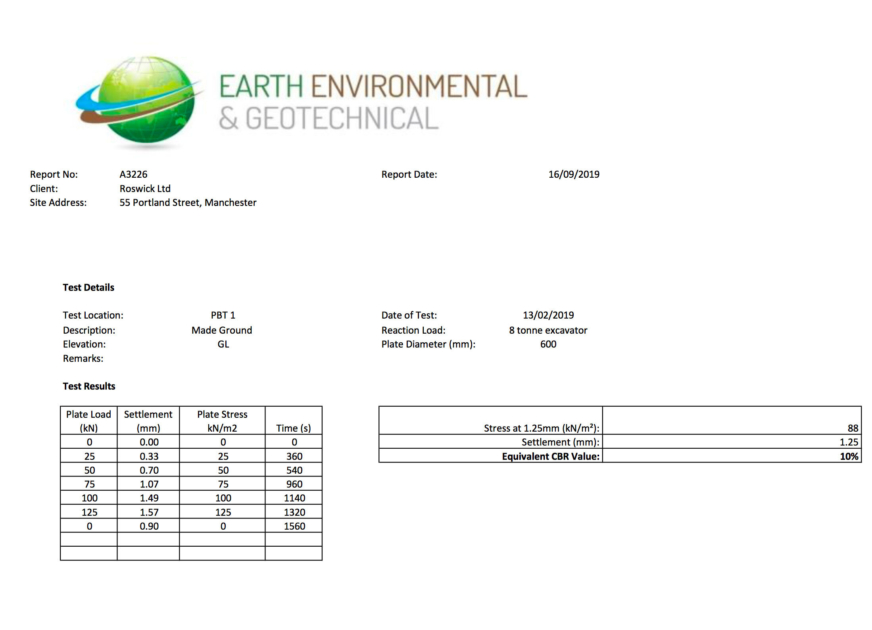

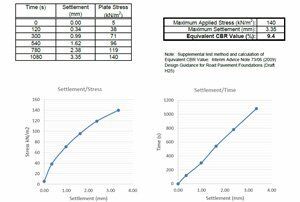

Example of a Plate Bearing Test

More Information on Site Investigation Services.

What Is the Site Investigation Process?

Site investigations are carried out with a phased approach

- Phase 1 Desk Study

- Phase 2 Intrusive Site Investigation

- Phase 3 Post Site Investigations

- Phase 4 Site Investigations Report

Step 1 – Complete the Phase I Desk Study and site walkover.

A Phase 1 Desk Study is a preliminary risk assessment report for a development site, often required for planning application approval.

Ideally, a Desk Study should also be accompanied by a walk over a survey conducted by an experienced practitioner. By compiling available information in relation to a site’s environmental, geological, hydrogeological, hydrological and mining setting, a cost-effective and focussed site investigation will be developed.

A Phase 1 Desk Study should always precede any ground investigation.Using the interpretive report to highlight potential development issues, environmental and cost liabilities requiring further investigation.

Step 2 – Phase 2 Intrusive Site Investigation

A Phase 2 assessment consists of an Intrusive Site investigation with quantitative risk assessment. The Phase 1 Desk Study will highlight the areas for further investigation and define the scope of these works. Any potential pollutant linkages can then be prioritised for investigation and depending on the Phase 1 Desk study report the appropriate investigation techniques utilised.

Step 3 – Post Site Investigations

Once the preliminary site investigations have been completed the results are analysed. If further site investigations are required these can be completed by our multi-disciplined team. These could include:

- Environmental Monitoring

- Soil Testing

- Geotechnical Monitoring

- Slope Stability Assessment

- Radon Monitoring

- Remediation Designs

- Gas protection measures.

Step 4 – Site Investigation Report

An interpretive report will then be compiled from all the information and data gathered from the ground investigations, testing, monitoring for the site.

Our Earth Environmental & Geotechnical consultants can discuss the details of the report and provide further services as required

Plate Bearing Tests for Wind Farms

Plate bearing tests also known as Plate Loading Tests are required for wind farms to establish the load bearing capacity of the ground and the anticipated settlement beneath the load of the ground where the wind farm will be installed.

The Plate Bearing Tests are required at the early stage of the wind farm development as part of the planning and method statement. The Plate Bearing Tests are required to sign off the “lifting plans” Plate Loading tests will also be required to ensure that the access roads and construction areas required during the wind farm installation project have the load bearing capacity for the heavy machinery required for the construction phase.

Before heavy machinery or temporary structures required during a Wind Farm Construction are installed it is essential to have an understanding of the ground conditions throughout the site and what equipment and structure the ground can support.

When is a Plate Bearing Test Used?

Plate bearing tests, defined in BS1377 part 9: 1990 and Eurocode 7, are used when designing any permanent or temporary structures to ensure safe loading. The Plate Bearing Tests are in -situ soil tests for civil engineering purposes.

Before heavy machinery or temporary structures like crane bases and pads for crane outriggers, piling mats or platforms are installed as part of the wind farm project it is essential to have an understanding of the ground conditions and what equipment and structure the ground can support.

A Plate Bearing Test determines the ultimate bearing capacity and settlement of the ground for working platforms, crane outrigger pads and piling mats.

What is involved in a Plate Bearing Test?

The Plate Bearing Test is carried out in accordance with BS 1377 Part 9: 1990 and consists of loading a steel plate and recording the settlement corresponding to each load increment.

Plate Bearing Test is normally carried out at foundation level, either on the surface or in a shallow pit. Plates of varying sizes up to 720mm diameter are available.

The loading plate is placed on the ground and connected via a load cell to a reaction load. Due to the larger size of the plate used (compared with a CBR test) this test is more suitable for testing larger aggregate backfills, however, it requires a larger reaction load.

Typically, a minimum 15tonne tracked excavator or other suitable plant is required for us to use as a reaction load.

Our engineers will advise on the plate size required to match the design load and reaction load required (i.e. size of excavator).

We can typically complete six tests in a day, subject to site conditions and can provide results the following day.

Earth Environmental & Geotechnical Ltd: Experienced Providers of Geotechnical Services for the Renewable Energy Sector

Earth Environmental & Geotechnical has Regional Offices throughout the UK providing nationwide coverage. We provide Geotechnical and Geo-environmental Consultancy Services for Renewable Energy Clients.

We work closely with the Wind Farm Design and Installation teams at the early stages of planning and method statement. Our extensive services give a detailed understanding of the ground conditions of the renewable energy development site including, solar farms, wind farms and battery storage facilities.

From the initial preliminary Phase 1 Desk Study, to detailed site investigations, our team have extensive experience and knowledge of the renewable energy sector supporting your projects success. We offer in-situ testing services which include CBR and Plate Bearing Tests, and pull out testing. Our team provide efficient, cost effective testing and rapid reporting of results. Plus advice and pragmatic design solutions on next steps where required.

Contact Us Now

Site Investigation Intrusive Techniques Examples:

- Cable Percussive Boreholes

- Window Sample Drilling

- Deep Window Sample Borehole

- Rock Coring

- Rotary Boreholes

- Rotary Core Drilling

- Dynamic Probing

- Trial Pits

- Trenches

- Windowless Sampling Rig

- Soakaway Testing

- Modular windowless sampling drilling rig

- Plate bearing testing

- California bearing ratio (CBR) testing